In recent years, there has been a notable shift in the industrial sector toward adopting eco-friendly whitening technologies. These advancements are driven by increasing environmental awareness and stricter regulations aimed at reducing the ecological footprint of manufacturing processes. Among the innovations gaining attention are fluorescent whitening agents and specialized optical brighteners designed for specific materials, such as Optical Brightener for PVC profiles. This article explores the progress made in these technologies and their significance for various industrial applications.

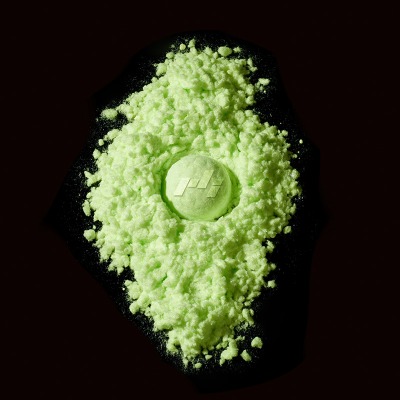

Fluorescent whitening agents (FWAs) play a crucial role in enhancing the appearance of materials by absorbing ultraviolet light and re-emitting it as visible blue light. This process helps counteract the natural yellowing of products, thereby making surfaces appear brighter and whiter. Traditionally, FWAs have been widely used in textiles, paper, and plastics due to their effectiveness in improving whiteness and brightness without altering the base material's properties. However, recent developments have focused on creating versions of fluorescent whitening agents that meet environmental standards while maintaining performance.

One key area of development is the formulation of FWAs with reduced environmental impact. Researchers and manufacturers are focusing on less hazardous substances during production and ensuring that the agents do not contribute to water pollution when washed off. These efforts align with broader industry goals of sustainability and regulatory compliance. As a result, eco-friendly fluorescent whitening agents now offer a balance between whitening efficacy and environmental responsibility, making them suitable for various industrial sectors.

The application of optical brighteners is not limited to general plastics but extends to specific materials such as PVC profiles. PVC, or polyvinyl chloride, is a widely used polymer in construction and manufacturing due to its durability and versatility. However, like many plastics, PVC can suffer from discoloration and dullness over time. To address this, optical brighteners for PVC profiles have been developed to enhance the whiteness and brightness of these materials, improving their aesthetic appeal and extending their service life.

Optical brighteners for PVC profiles are specially formulated to integrate seamlessly with the polymer matrix. Their function is similar to that of fluorescent whitening agents but tailored to the unique chemical and physical properties of PVC. By absorbing UV radiation and emitting visible light, these brighteners help maintain a consistent white appearance, which is particularly important in building materials where visual quality can affect consumer perception. The advancements in optical brighteners for PVC profiles also consider the material's resistance to weathering and aging, ensuring long-lasting effects.

The adoption of eco-friendly fluorescent whitening agents and optical brighteners for PVC profiles reflects a broader trend in industrial manufacturing towards sustainability. Industries are increasingly evaluating the environmental impact of their raw materials and additives, prompting a demand for solutions that do not compromise on functionality. These whitening technologies have evolved to address this demand, offering formulations that reduce hazardous components while delivering consistent performance in whitening and brightness enhancement.

Another notable development is the improvement in the stability and compatibility of fluorescent whitening agents with various industrial substrates. Modern FWAs are engineered to resist degradation from heat, light, and chemical exposure, which extends the lifespan of treated products. This is especially important in applications involving outdoor exposure or high-temperature processing, such as automotive parts or construction materials. The durability of optical brighteners for PVC profiles has also been enhanced, ensuring that whitening effects endure under harsh environmental conditions.

Environmental regulations have played a significant role in shaping these advancements. Restrictions on heavy metals, formaldehyde, and certain aromatic amines in chemical additives have led to the reformulation of many fluorescent whitening agents. Manufacturers have adopted greener synthesis routes and bio-based raw materials, contributing to lower toxicity and improved biodegradability. This regulatory-driven innovation benefits industrial users by providing safer alternatives that reduce environmental liabilities and support corporate sustainability initiatives.

From an application perspective, the versatility of fluorescent whitening agents allows them to be incorporated into various industrial products beyond textiles and plastics. These agents are now increasingly used in coatings, adhesives, and packaging materials, where enhanced whiteness can improve product appeal and perceived quality. Similarly, optical brighteners for PVC profiles have found use in a broad range of construction and architectural products, such as window frames, siding, and decorative panels, where maintaining a bright white finish is desirable.

In conclusion, the progress in eco-friendly whitening technologies, particularly fluorescent whitening agents and optical brighteners for PVC profiles, marks a significant step towards sustainable industrial manufacturing. These advancements not only address environmental concerns but also enhance product quality and durability. As industries continue to prioritize green solutions, the demand for whitening agents that combine environmental responsibility with functional benefits is expected to grow. The ongoing research and innovation in this field promise further improvements in the performance and sustainability of whitening technologies for diverse industrial applications.

EN

EN 中文

中文 ES

ES

.jpg)