The textile industry has long relied on whitening and brightening solutions to improve the aesthetic appeal of fabrics. Among the key components in these solutions are fluorescent whitening agents, which have played a significant role in enhancing the whiteness and brightness of textiles for decades. As consumer preferences evolve and environmental concerns grow, new trends are shaping the development and application of these agents, including innovations related to Optical Brightener for PVC profiles used in textile processing equipment and accessories.

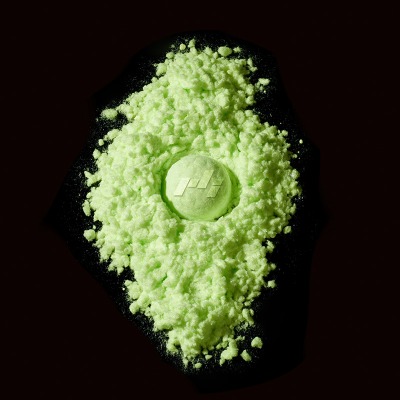

Fluorescent whitening agents are chemical compounds that absorb ultraviolet light and re-emit it as visible blue light, making materials appear brighter and whiter. Their effectiveness in textiles comes from their ability to counteract the yellowish tint that natural fibers and some synthetic fabrics may exhibit. Traditionally, fluorescent whitening agents have been applied during fabric finishing processes to enhance the visual quality of clothing, home textiles, and industrial fabrics. However, recent developments indicate a shift towards more sustainable and multifunctional formulations that meet both aesthetic and regulatory demands.

One emerging trend is the increased focus on eco-friendly fluorescent whitening agents. Many textile manufacturers are seeking agents that are not only effective but also biodegradable and free from harmful substances such as heavy metals or hazardous solvents. This shift is driven by stricter environmental regulations and growing consumer awareness about the ecological footprint of textile products. As a result, chemical suppliers are developing new fluorescent whitening agents derived from safer raw materials and with improved biodegradability, which helps less environmental impact while maintaining the desired whitening effect.

In parallel, the use of optical brighteners for PVC profiles is gaining attention in the textile sector. PVC profiles are often used in the manufacturing of textile machinery components, such as rollers, guides, and conveyor belts, where durability and visual quality are critical. Optical brighteners incorporated into PVC profiles help maintain a clean and bright appearance, resisting discoloration caused by dust, oils, and exposure to light. This not only enhances the longevity of the equipment but also contributes indirectly to the quality of textile products by ensuring consistent processing conditions.

Another noteworthy trend involves the integration of fluorescent whitening agents with other functional additives. For example, combining whitening agents with antimicrobial or UV-resistant compounds allows textiles to gain additional performance benefits. This multifunctionality is particularly important for applications such as sportswear, medical textiles, and outdoor fabrics, where brightness alone is not sufficient. The ability of fluorescent whitening agents to maintain their whitening effect while coexisting with other additives reflects advances in chemical engineering and formulation science.

Additionally, digital textile printing has introduced new challenges and opportunities for fluorescent whitening agents. The precision and customization offered by digital printing require whitening agents that do not interfere with ink adhesion or color fastness. Modern fluorescent whitening agents are being tailored to work harmoniously with various printing technologies, enabling bright and vivid patterns without compromising the underlying whiteness of the fabric. This has expanded the range of textile products that can benefit from these agents, from fashion apparel to interior decor.

The market for optical brighteners for PVC profiles is also evolving, with a growing emphasis on thermal stability and resistance to mechanical wear. Textile machinery operates under demanding conditions, often involving high temperatures and continuous friction. Optical brighteners used in PVC profiles must withstand these stresses without degrading or yellowing. Innovations in polymer additives and processing techniques have improved the performance of optical brighteners in PVC, resulting in more durable and visually appealing components that support efficient textile production.

Moreover, the demand for transparent and translucent textiles in fashion and technical applications has spurred interest in fluorescent whitening agents that perform well on delicate or thin fabrics. These agents need to provide effective brightening without altering the fabric’s natural texture or translucency. Research in this area is ongoing, with new compounds being evaluated for their compatibility with various fiber types, including nylon, polyester, and blends. Achieving the right balance of whitening and fabric integrity remains a focus for scientists and manufacturers alike.

Sustainability also drives innovation in the recycling of textiles treated with fluorescent whitening agents. The presence of these agents can affect recycling processes, particularly in chemical recycling and fiber regeneration. Industry efforts are underway to develop fluorescent whitening agents that do not hinder recycling or to create effective methods for removing or neutralizing these compounds during textile recovery. This approach supports circular economy goals while maintaining the benefits of whitening technologies.

In conclusion, the field of textile whitening and brightening is undergoing significant changes influenced by environmental considerations, technological advances, and shifting consumer demands. Fluorescent whitening agents continue to be essential for achieving desirable fabric aesthetics, while innovations in their formulation and application open new possibilities. Simultaneously, optical brighteners for PVC profiles contribute to the overall quality and durability of textile manufacturing equipment. Together, these developments point toward a future where whitening and brightening solutions are more sustainable, multifunctional, and aligned with the needs of modern textile production.

EN

EN 中文

中文 ES

ES

.jpg)