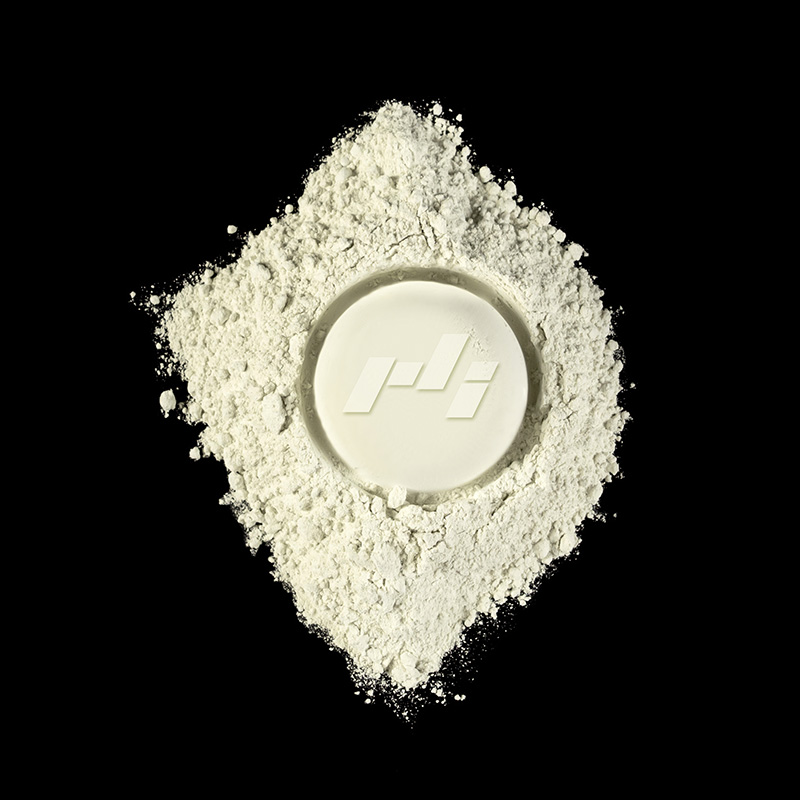

Fluorescent Brightener and Optical Brightener for Plastic are additives widely used in the plastics industry to enhance the visual qualities of products during processing. These brightening agents work by absorbing ultraviolet light and re-emitting it as visible blue light, which compensates for natural yellowing in plastics. The result is a more balanced, visually appealing white or light-colored appearance that remains consistent across different batches. Their application extends to materials such as PVC, polystyrene, polyethylene, and polypropylene, providing manufacturers with a practical solution for maintaining product uniformity.

Role in Whitening Plastic Products

The addition of a fluorescent brightener during plastic processing helps correct color deviations that may occur due to raw material variations or thermal exposure. In rigid and soft PVC products, for example, even minor yellowing caused by heat or stabilizers can affect the perceived quality of the final product. Using an optical brightener for plastic counteracts this effect, giving a cleaner and more uniform appearance without altering the material’s fundamental properties. In polystyrene products, these additives enhance whiteness and improve the transparency of translucent parts, which is particularly relevant for packaging and consumer goods.

By integrating the brightener at an early stage of production, manufacturers can ensure a consistent color appearance throughout the entire batch. This helps in avoiding visual inconsistencies that could arise from different processing cycles, maintaining the aesthetic standard of products while simplifying quality control procedures.

Performance Under Processing Conditions

Fluorescent brighteners are designed to maintain their function under the thermal and chemical conditions commonly encountered in plastic manufacturing. They show stability at elevated temperatures, ensuring that the whitening effect remains effective even during extrusion or molding processes. Similarly, their resistance to chemical exposure allows them to remain functional in the presence of additives such as stabilizers, plasticizers, and colorants. This stability supports predictable results, enabling manufacturers to achieve the intended visual effect without repeated adjustments or testing.

The low dosage requirement of these additives also contributes to efficient processing. Even at small concentrations, a fluorescent brightener can noticeably enhance brightness, which allows for reduced material costs. This practical aspect makes them a widely adopted option for both industrial and consumer product applications.

Contribution to Product Consistency

Consistency is a central consideration in plastic manufacturing, particularly for products that are produced in large volumes. Optical brighteners for plastic help maintain visual uniformity across multiple production runs. By reducing the variability in color and brightness, these additives support stable product appearance and reduce the likelihood of rejection due to aesthetic differences.

In addition to whitening, some fluorescent brighteners can offer mild UV protection, helping to limit color changes when products are exposed to sunlight. This can be especially relevant for outdoor applications or items expected to retain their appearance over time. While they are not a replacement for dedicated UV stabilizers, they contribute to maintaining the original look of plastic products.

Flexibility and Compatibility

Fluorescent brighteners are compatible with a range of plastic formulations and can be used alongside other additives without adverse interactions. This versatility allows manufacturers to adjust the brightener level to suit specific production goals, such as achieving a particular shade of white or enhancing the brightness of transparent parts. They are suitable for both single-material products and blends, ensuring that the visual effect is consistent across complex formulations.

This compatibility also extends to different processing methods, including extrusion, injection molding, and calendaring. By incorporating the brightener at the appropriate stage, producers can integrate it seamlessly into the workflow without affecting equipment or processing parameters.

Practical Application Guidelines

Typical usage of fluorescent brighteners in plastic ranges from 0.01% to 0.06% by weight for whitening purposes, depending on the type of material and the desired visual outcome. For anti-reflection or minor color corrections, smaller amounts can be applied. It is generally recommended to evenly disperse the brightener within the plastic matrix to ensure uniform performance. For products such as PVC sheets, films, and molded parts, careful control of additive concentration can help achieve a consistent white appearance while maintaining other material characteristics such as strength and flexibility.

EN

EN 中文

中文 ES

ES

.jpg)